1. Powder Coat In Oven Overview and Structure

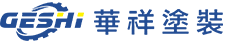

A Powder Coat In Oven is a thermal curing system designed to bond powder coatings to metal surfaces. Its core components include an insulated chamber, heating elements (electric, gas, or infrared), precision temperature controls, airflow systems, and racks or conveyors. Advanced models feature automated loading mechanisms and energy-efficient insulation for uniform heat distribution.

These Powder Coat In Ovens are essential in automotive manufacturing, architectural metalwork, furniture production, and industrial machinery. They cure coatings on car parts, aluminum window frames, appliances, and agricultural equipment, ensuring scratch-resistant, corrosion-proof finishes.

Entry-level manual ovens start at 6,000,whileautomatedindustrialsystemsexceed60,000. Pricing depends on size, heating technology, and customization. Infrared ovens typically cost 20% more than gas models due to faster curing and lower energy waste.

Preheat the oven to 160–220°C based on coating specifications. Arrange items to allow airflow between surfaces. Monitor curing cycles using integrated timers and avoid opening the door mid-process. Clean residue weekly to prevent contamination.

Evaluate production volume, workspace dimensions, and coating types. Small workshops benefit from compact electric ovens, while factories prioritize gas-powered conveyor systems. Seek ENERGY STAR-certified units and warranties covering heating elements.

Install explosion-proof ventilation to manage fumes and dust. Use flame-resistant gloves and face shields during loading. Regularly inspect gas lines in LPG ovens and ensure emergency stop buttons are functional.

7. Design Efficiency of Powder Coat In Ovens

Modern designs reduce energy consumption by 30% through heat-recovery systems and ceramic fiber insulation. Modular chambers enable easy scaling for large projects, while smart controls minimize overheating risks.

Q Are powder coat in ovens eco-friendly?

A Yes, electric and infrared models emit minimal pollutants, aligning with green manufacturing standards.

Q How to maintain a Powder Coat In Oven?

A Replace air filters monthly and calibrate thermostats annually to sustain performance.

Q Can these ovens cure custom-sized items?

A Adjustable rack systems and modular chambers support oversized components like HVAC ducts.

Q What safety certifications matter?

A Look for UL or CE marks, ensuring compliance with fire and electrical safety regulations.

Q Do they work with metallic powders?

A Yes, precise temperature settings accommodate specialty coatings like chrome or copper finishes.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com